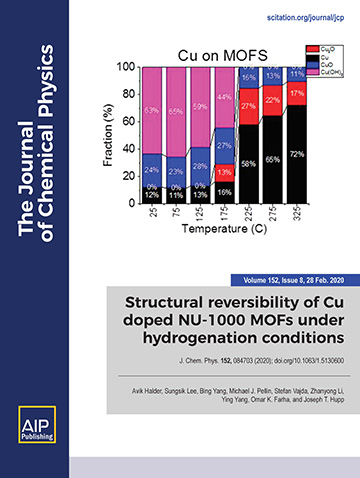

The metal–organic framework (MOF), NU-1000, and its metalated counterparts have found proof-of-concept application in heterogeneous catalysis and hydrogen storage among others. A vapor-phase technique, akin to atomic layer deposition (ALD), is used to selectively deposit divalent Cu ions on oxo, hydroxo-bridged hexa-zirconium(IV) nodes capped with terminal –OH and –OH2 ligands. The subsequent reaction with steam yields node-anchored, CuII-oxo, hydroxo clusters. We find that cluster installation via AIM (ALD in MOFs) is accompanied by an expansion of the MOF mesopore (channel) diameter. We investigated the behavior of the cluster-modified material, termed Cu-AIM-NU-1000, to heat treatment up to 325˚C at atmospheric pressure with a low flow of H2 into the reaction cell. The response under these conditions revealed two important results: (1) Above 200˚C, the initially installed few-metal-ion clusters reduce to neutral Cu atoms. The neutral atoms migrate from the nodes and aggregate into Cu nanoparticles. While the size of particles formed in the MOF interior is constrained by the width of mesopores (∼3 nm), the size of those formed on the exterior surface of the MOF can grow as large as ∼8 nm. (2) Reduction and release of Cu atoms from the MOFs nodes is accompanied by the dynamic structural transformation of NU-1000 as it reverts back to its original dimension following the release. These results show that while the MOF framework itself remains intact at 325˚C in an H2 atmosphere, the small, AIM-installed CuII-oxo, hydroxo clusters are stable with respect to reduction and conversion to metallic nanoparticles only up to ∼200˚C.

DOI: 10.1063/1.5130600

Single non-heme Fe(II) ions present as structural moieties in several metal–organic frameworks (e.g., MIL-100, MIL-101, and MIL-808, where MIL indicates Materials of Institute Lavoisier) are identified by Kohn–Sham density functional calculations as promising catalysts for C–H bond activation, with energetic barriers as low as 40 kJ mol–1 for ethane and 60 kJ mol–1 for methane following the oxidative activation of iron. The rate-determining step is the activation of N2O and has a barrier of 140 kJ mol–1. Through consideration of the full reaction profile leading to the corresponding alcohols, ethanol and methanol, we have identified key changes in the chemical composition of the node that would modulate catalytic activity. The thermal and chemical stabilities of these materials, together with the scalability of their syntheses, make them attractive catalysts for the selective low-temperature conversion of light alkanes to higher-value oxygenates.

A chemically and thermally stable, mesoporous, crystalline metal–organic framework, NU-1000, serves as a structurally well-defined support for catalytic reactions. Depositing chromium(III), a metal widely used in homogeneous ethylene oligomerization catalysts, onto the Zr6 node of NU-1000 allows for the atomically precise determination of the structure of the Cr3+ catalyst through single-crystal X-ray diffraction studies. Chromium modification of NU-1000 was accomplished via solvothermal deposition in MOFs (SIM); termed Cr-SIM-NU-1000, the elaborated material features individual Cr atoms directed in single-site fashion into the mesopore of NU-1000. It was found that NU-1000 serves to stabilize the catalyst against both the typical chemical deactivation of homogeneous systems and leaching from heterogeneous systems. Cr-SIM-NU-1000 exhibits superior catalytic activity, as compared to Cr2O3, for ethylene oligomerization, with 20% conversion at a turnover frequency of about 60 h –1 and products ranging from C8–C28. Given that this catalysis occurs at low temperature (ambient) and low pressure (1 bar C2H4), along with minimal quantity of cocatalyst, the high activity shown by Cr-SIM-NU-1000 enables significant reduction in materials usage and waste. Postcatalytic characterization reveals Cr-SIM-NU-1000 remains intact with no leaching under the reaction conditions.

Recent progress in the synthesis and characterization of metal–organic frameworks (MOFs) has opened the door to an increasing number of possible catalytic applications. The great versatility of MOFs creates a large chemical space, whose thorough experimental examination becomes practically impossible. Therefore, computational modeling is a key tool to support, rationalize, and guide experimental efforts. In this outlook we survey the main methodologies employed to model MOFs for catalysis, and we review selected recent studies on the functionalization of their nodes. We pay special attention to catalytic applications involving natural gas conversion.

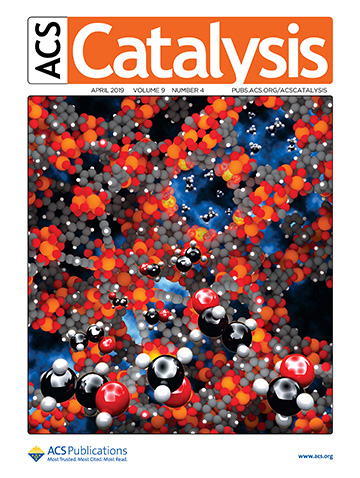

Copper oxide clusters synthesized via atomic layer deposition on the nodes of the metal–organic framework (MOF) NU-1000 are active for oxidation of methane to methanol under mild reaction conditions. Analysis of chemical reactivity, in situ X-ray absorption spectroscopy, and density functional theory calculations are used to determine structure/activity relations in the Cu-NU-1000 catalytic system. The Cu-loaded MOF contained Cu-oxo clusters of a few Cu atoms. The Cu was present under ambient conditions as a mixture of ∼15% Cu+ and ∼85% Cu2+. The oxidation of methane on Cu-NU-1000 was accompanied by the reduction of 9% of the Cu in the catalyst from Cu2+ to Cu+. The products, methanol, dimethyl ether, and CO2, were desorbed with the passage of 10% water/He at 135˚C, giving a carbon selectivity for methane to methanol of 45–60%. Cu oxo clusters stabilized in NU-1000 provide an active, first generation MOF-based, selective methane oxidation catalyst.

DOI: 10.1021/jacs.7b02936

Zr-based metal–organic frameworks (MOFs) have been shown to be excellent catalyst supports in heterogeneous catalysis due to their exceptional stability. Additionally, their crystalline nature affords the opportunity for molecular level characterization of both the support and the catalytically active site, facilitating mechanistic investigations of the catalytic process. We describe herein the installation of Co(II) ions to the Zr6 nodes of the mesoporous MOF, NU-1000, via two distinct routes, namely, solvothermal deposition in a MOF (SIM) and atomic layer deposition in a MOF (AIM), denoted as Co-SIM+NU-1000 and Co-AIM+NU-1000, respectively. The location of the deposited Co species in the two materials is determined via difference envelope density (DED) analysis. Upon activation in a flow of O2 at 230˚C, both materials catalyze the oxidative dehydrogenation (ODH) of propane to propene under mild conditions. Catalytic activity as well as propene selectivity of these two catalysts, however, is different under the same experimental conditions due to differences in the Co species generated in these two materials upon activation as observed by in situ X-ray absorption spectroscopy. A potential reaction mechanism for the propane ODH process catalyzed by Co-SIM+NU-1000 is proposed, yielding a low activation energy barrier which is in accord with the observed catalytic activity at low temperature.

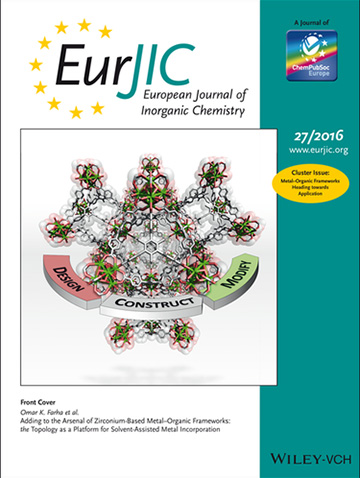

Gaining control over the assembly of mesoporous Zr‐based metal–organic frameworks (MOFs) with modifiable metal nodes remains a challenge. The the topology is intriguing, particularly if considering postsynthetic modification, as it presents large sodalite‐like cages surrounded by 12 interconnected 1D channels that allow for efficient diffusion of guest molecules throughout the structure. Herein, we demonstrate the first Zr MOF with the topology, NU‐1200, which was synthesized by controlling the geometry of the organic building unit. In addition, by using NU‐1200 as a platform, we perform solvent‐assisted metal incorporation to form single‐site metalated nodes, a process that is characterized by single‐crystal X‐ray diffraction.

Department of Chemistry

207 Pleasant Street SE, Minneapolis, MN, 55455

P: 612-301-1491 | E: icdc@umn.edu