12/14/2007

Tough Nanoporous Membranes with a 3-D pore structure

Recent research from the group of Professor Marc

Hillmyer.

Controlled

fabrication of nanoporous polymer membranes has attracted growing interest

due to their applicability as catalyst supports, ultrafiltation membranes,

or templates for the synthesis of other nanomaterials. It has been generally

shown that self-assembled block copolymers comprising a non-degradable

block (matrix) such as polystyrene (PS) and a chemically-etchable block

such as polylactide (PLA) can be used to generate nanoporous materials

upon removal of the sacrificial component. However, in most cases the nanoporous

materials made by this route suffer from poor mechanical performance and

limited chemical and thermal stability. While crosslinking the matrix material

has shown promise in improving the thermal properties, the lack of toughness

in these materials is still a significant issue.

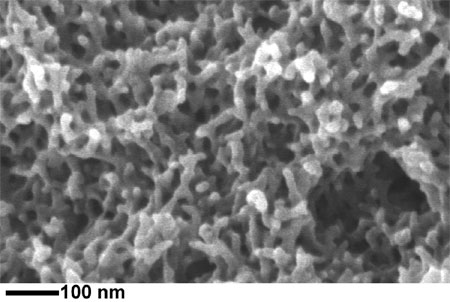

Targeting novel nanoporous

polymer membranes that are chemically, thermally and mechanically robust,

graduate student Liang Chen working with Professor Marc Hillmyer integrated

polydicyclopentadiene (polyDCPD), a strong thermosetting material prepared

by Ring-Opening Metathesis Polymerization (ROMP), and PLA into thin polymeric

films. By incorporating a "doubly" reactive block copolymer containing

etchable PLA and ROMP-reactive PNS (see chemical structures below) during

the ROMP of DCPD using Grubbs catalyst, Liang prepared a nanoscopically

organized composite film. Removal of the PLA by treatment with aqueous

base yielded a nanoporous membrane (average pore diameter of 17 nm) with

a high porosity (40%), a large specific surface area (160 m2 g–1),

and narrow pore size distribution. The resulting mesoporous polyDCPD composite

membranes were thermally stable up to 140 °C, and exhibited remarkable

toughness comparable to the parent polyDCPD. The three dimensionally continuous

pore structure was confirmed by a combination of scanning electron microscopy

(see image below), ionic conductivity and gas diffusion measurements. Potential

applications of these novel membranes as high surface area catalyst supports,

size selective membranes, and nanomaterial templates are currently being

explored. This work was recently been published in the Journal

of the American Chemical Society (volume

129, pages 13786–13787).

|