10/22/2007

Playing

Rubik's Cube with Nanoparticles

Recent Research from the group of Professor Andreas

Stein.

Atomic and ionic

crystals pack atoms in a wide range of periodic motifs. When the building

blocks are larger than atoms – uniform, spherical nanoparticles or

colloids with sizes between around 10 and 100 nanometers – the resulting

colloidal crystals typically assume a dense face-centered-cubic (fcc) order. Such colloidal crystals are of great interest

in the growing field of photonics, where they may be used to manipulate

the propagation or emission of light. However, if the choice of a photonic

crystal structure is limited to fcc, optical properties are also restricted.

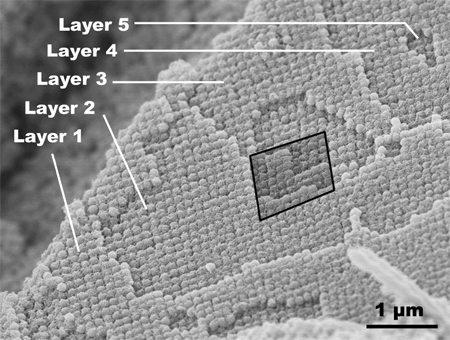

Graduate student

Fan Li and senior Sarah Delo in Professor Stein's group recently discovered

an unusual approach to assemble nearly cubic nanoparticles into ordered

arrays with simple cubic rather than fcc symmetry. Surprisingly, they achieved this with a

template or mold consisting of fcc-packed

polymer spheres. After these were infiltrated with a surfactant and with

precursors for titania-phosphorus oxide composites and subsequently heated

to 400 °C, the majority of the product showed periodic arrays of tiny cubes

as depicted in the scanning electron micrograph in Figure 1. Multiple layers

are clearly visible, in which square arrangements of particles sit directly

on similarly arranged cubes in adjacent layers, forming a simple cubic

structure.

Figure 1. Titania-phosphorus oxide cubes in simple cubic pattern.

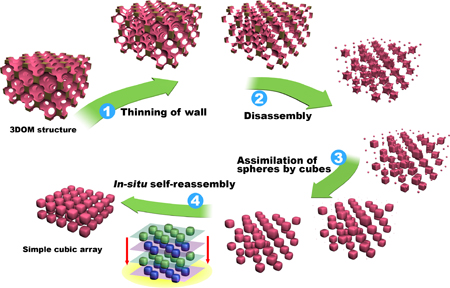

On

the basis of structural and compositional analyses, Stein and coworkers

proposed the mechanism outlined in Figure 2 for the product formation.

When the precursor hardens within the fcc colloidal

crystal template it initially forms a three-dimensionally ordered macroporous

(3DOM) skeleton. During sample heating the skeletal walls shrink and

eventually break down into small, nearly identical building blocks,

still in an fcc arrangement.

However, at the processing temperature, the phosphorus oxide component

forms a liquid phase. Resulting capillary forces move the particles

closer together, so that adjacent layers merge, forming the simple cubic

array.

Figure 2. Proposed mechanism for the structural transformation from face-centered cubic to simple cubic.

In their publication (Angew. Chem. Int. Ed. 2007, 46, 6666, http://dx.doi.org/doi:10.1002/anie.200701553),

Li et al. conclude that "Even though the structures created in

the present work are far away from the perfection necessary for

photonic crystals, an adaptation of the self-reassembly method

may provide a faster, low cost alternative to produce simple cubic

photonic crystals that are normally prepared by elaborate micromachining,

layer-by-layer lithography, holography and macroporous silicon

etching, all expensive and time-consuming methods." This

work was also highlighted in a Nature New & Views article (Nature

2007, 449, 550. http://dx.doi.org/doi:10.1038/449550a)

|